PK VESTA PLANT

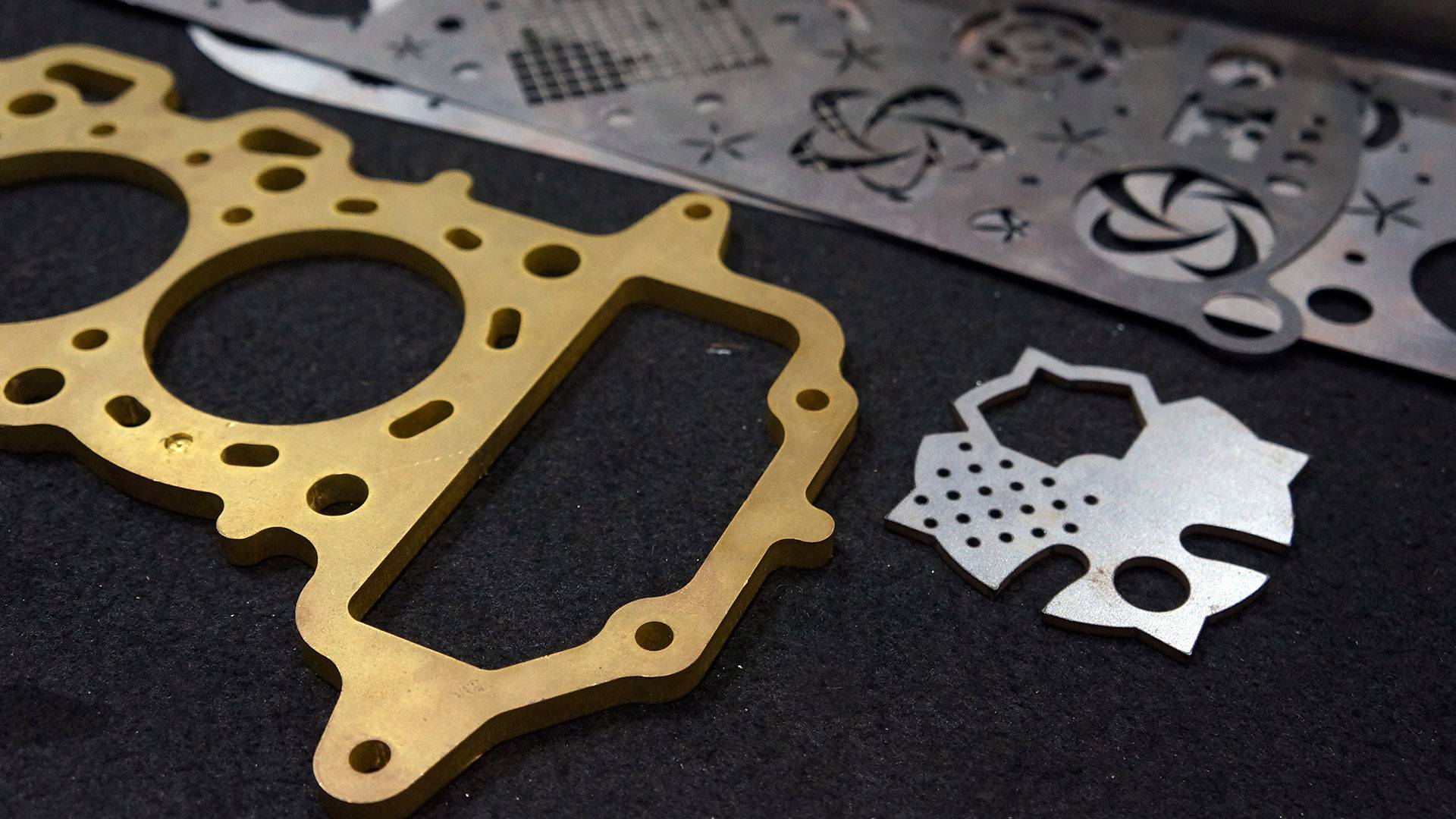

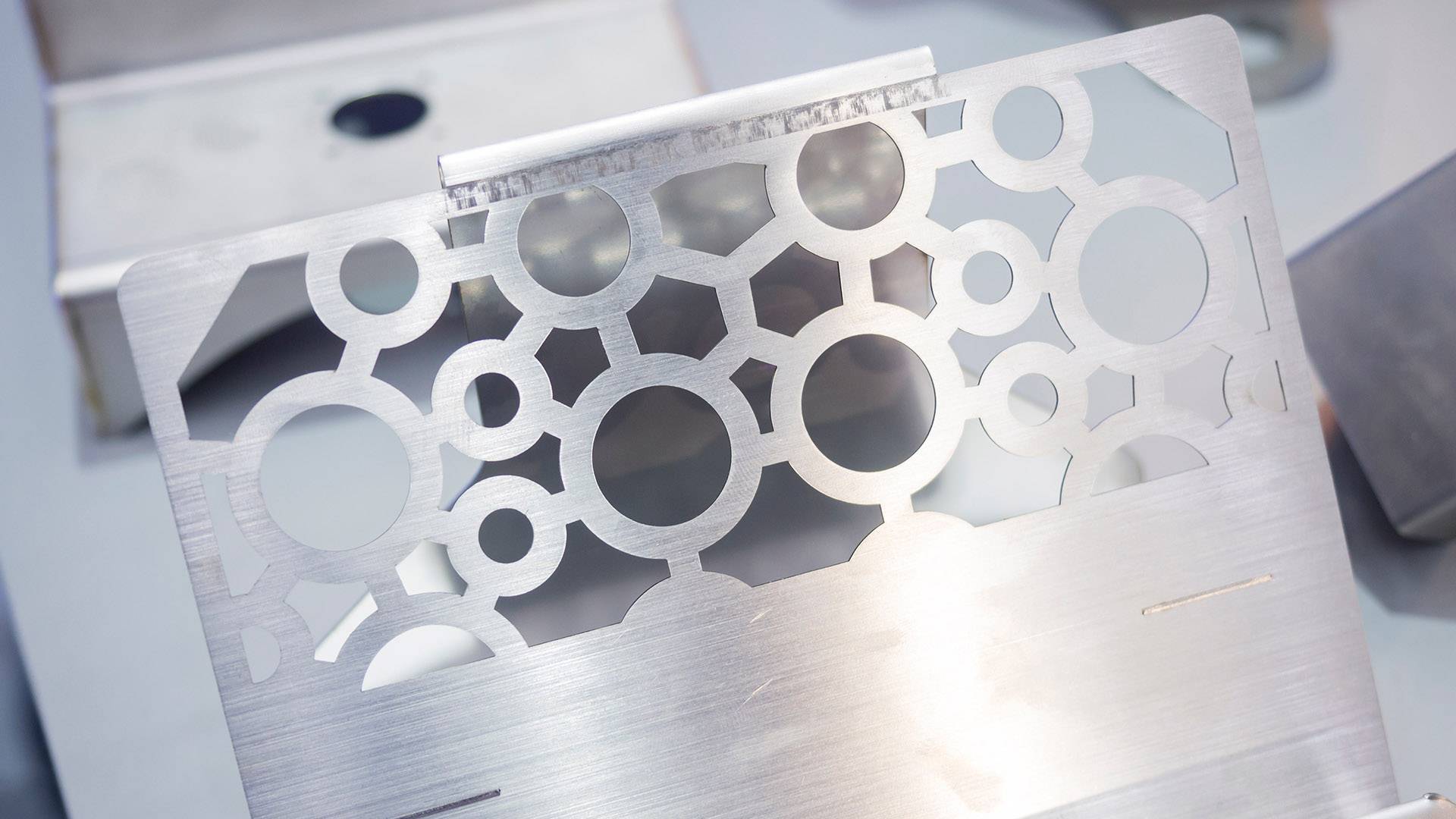

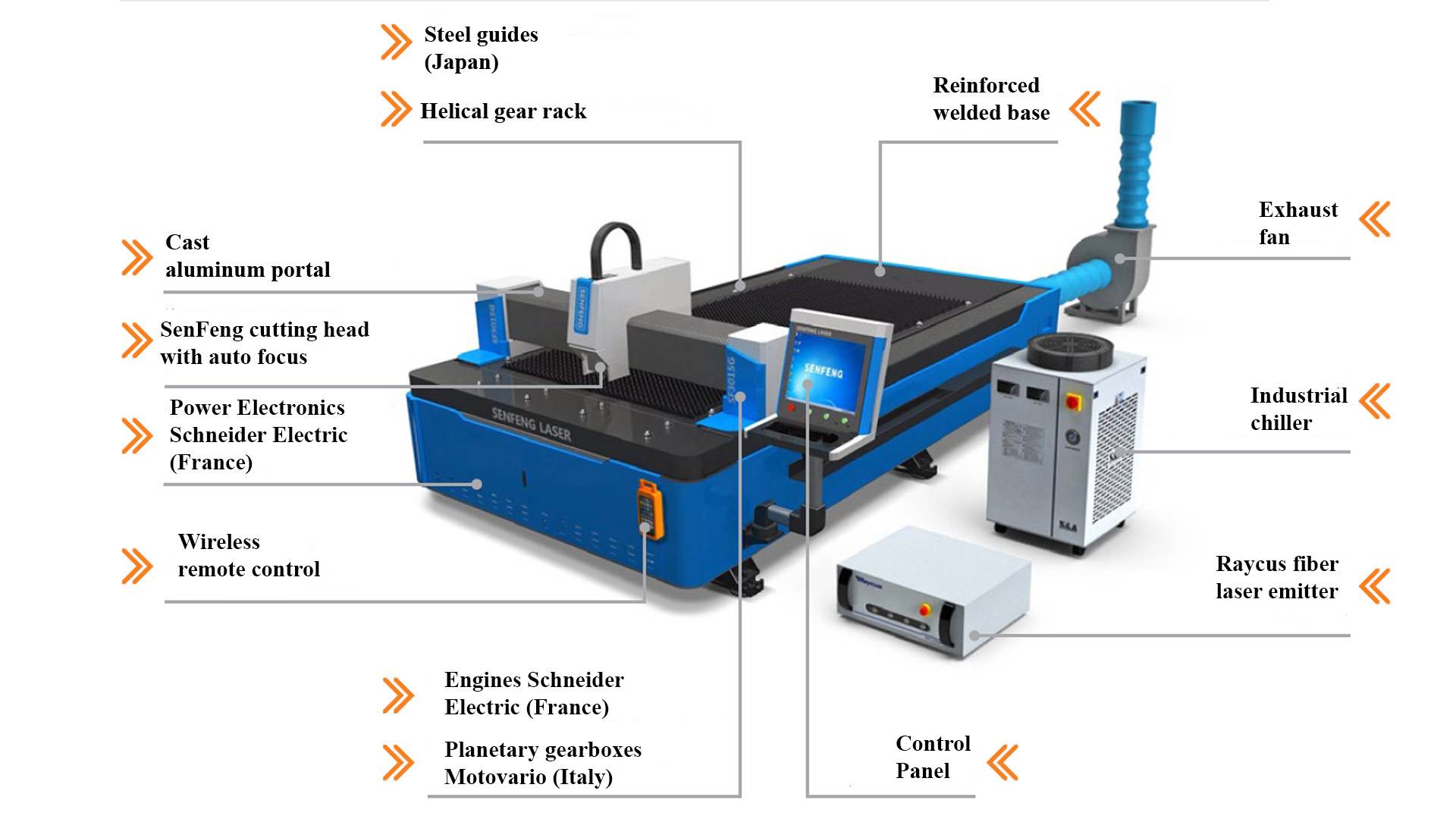

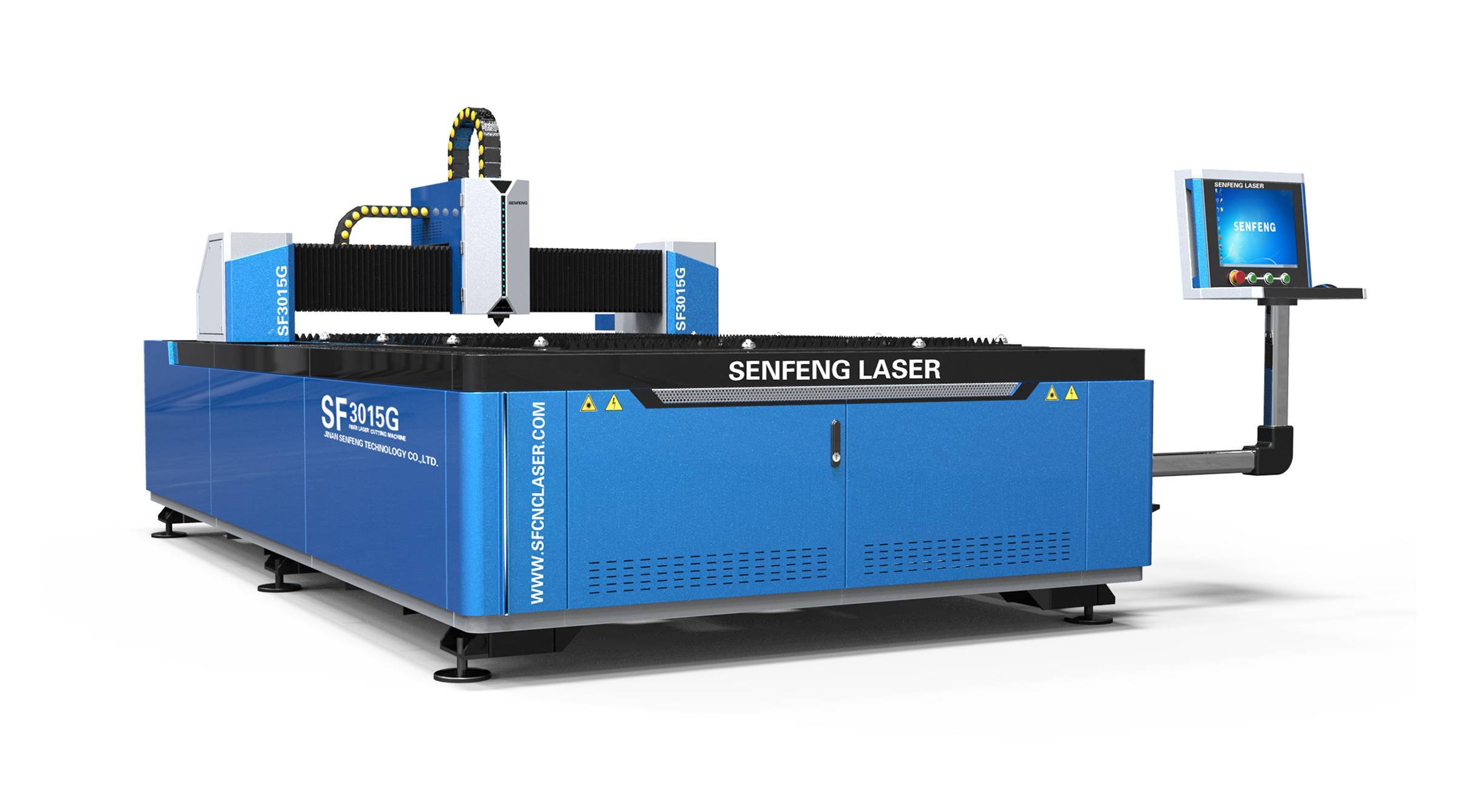

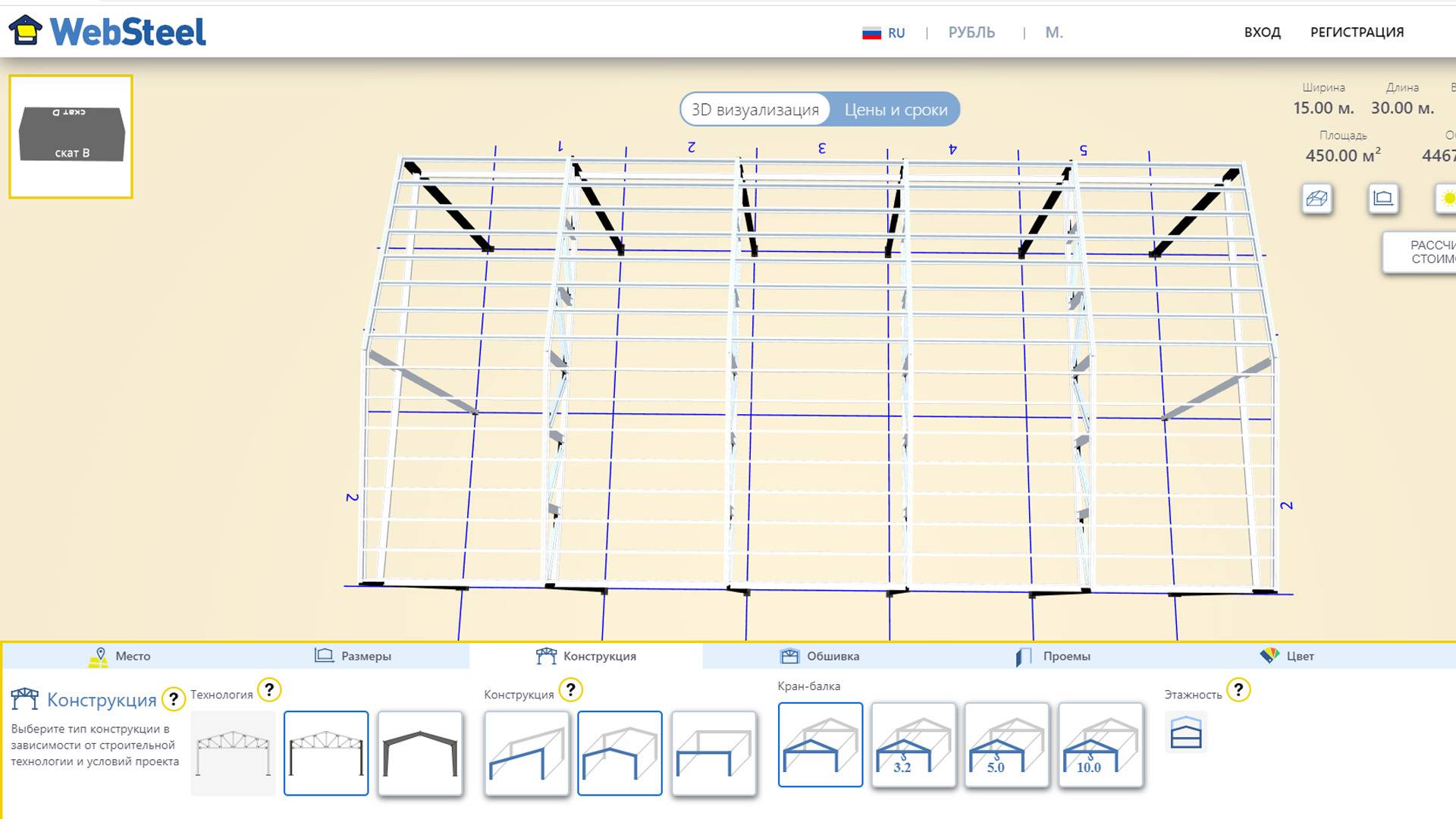

"The industrial company PK VESTA has been operating in the construction market in Russia and abroad since 1991, offering modern solutions in the design, manufacture and construction of prefabricated steel buildings made out of light metal structures (LSGF and Rigid Framing), as well as metal processing services for Russian and international customers.

A distinctive feature of the plant is a unique business model based on the high-tech online service WebSteel, which allows serving all customers online 24/7"